2025's Top 10 CNC Laser Cutters for Metal: Find Your Perfect Match!

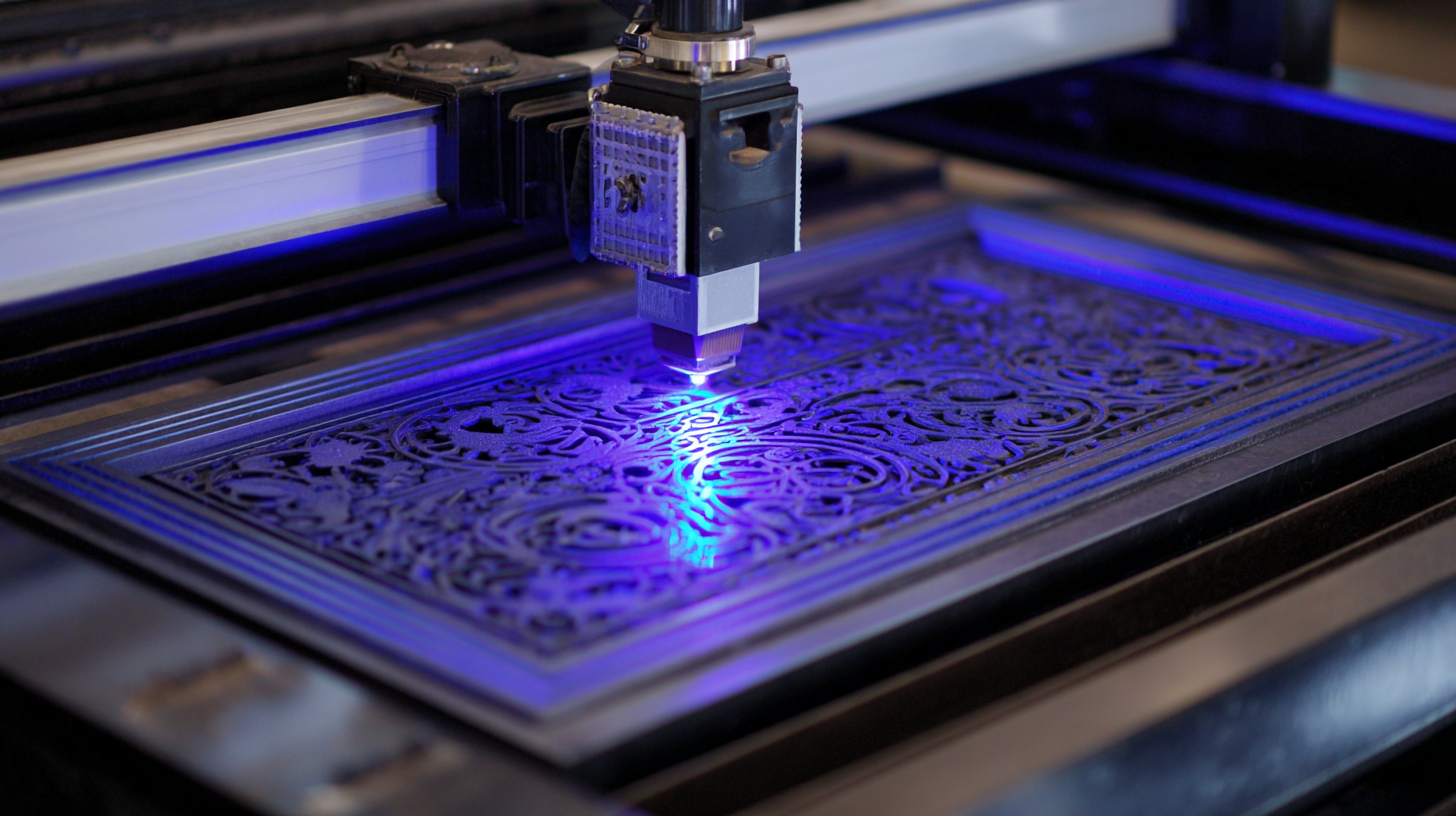

In the ever-evolving landscape of metal fabrication, precision and efficiency are paramount. As we move into 2025, the demand for advanced machinery continues to rise, and CNC laser cutters for metal have emerged as a game-changer for various industries. These innovative tools not only enhance cutting capacity but also provide unmatched accuracy, enabling manufacturers to achieve intricate designs with ease. Navigating the diverse market of CNC laser cutters can be daunting, given the multitude of options available, each boasting unique features and capabilities.

In this article, we will explore the top 10 CNC laser cutters for metal in 2025, carefully selected based on performance, reliability, and technological advancements. Whether you're a seasoned professional in the metalworking sector or a hobbyist looking to invest in a reliable machine, our comprehensive guide will help you find your perfect match. By highlighting the strengths and specifications of each model, we aim to equip you with the knowledge needed to make an informed decision and streamline your metal fabrication processes. Join us as we delve into the future of CNC laser cutting technology and discover how these tools can transform your projects into precision-engineered realities.

Top Features to Look for in CNC Laser Cutters for Metal

When choosing a CNC laser cutter for metal, several top features must be considered to ensure optimal performance and efficiency. First and foremost, the power of the laser is crucial, as it directly affects the cutter's ability to handle various materials and thicknesses. A higher wattage typically allows for faster cutting speeds and cleaner edges, making it easier to achieve precise results on thick metals like steel or aluminum. Additionally, consider the laser type, such as CO2 or fiber lasers, each having its advantages depending on the application.

Another essential feature is the cutting area and bed size. A larger cutting area provides the flexibility to work on bigger projects without the need for multiple setups. Moreover, software compatibility plays a vital role in the usability of the CNC laser cutter. It's important to select a machine that works seamlessly with design software for smooth operation from design to cut.

Lastly, look for advanced features like automated focus control and real-time monitoring systems, as these can significantly enhance the cutting process and reduce the likelihood of errors, ultimately maximizing productivity.

Comparative Analysis of Leading Brands in 2025

As we look forward to 2025, the competitive landscape of CNC laser cutters for metal continues to evolve rapidly. A comparative analysis of leading brands highlights key factors such as cutting speed, precision, and operational cost, making it essential for businesses to select the right equipment to enhance productivity. Reports indicate that the global market for CNC laser cutting machines is projected to grow significantly, driven by advancements in technology and increasing demand in sectors such as automotive and aerospace. According to industry data, the market valuation was estimated at approximately $5 billion in 2023, with an expected CAGR of 7.2% over the next few years.

In examining the top contenders in the market, it's crucial to consider metrics beyond just hardware specifications. Factors like user-friendliness, customer support, and integration capabilities with existing manufacturing processes play a vital role in the selection process. Notably, brands that offer robust software solutions alongside their machines can greatly streamline operations and enhance overall efficiency. Furthermore, a qualitative comparative analysis of customer reviews indicates that satisfaction levels are highest among users who prioritize after-sales service and long-term support, which are becoming increasingly important in the decision-making process for businesses investing in CNC technology.

Budgeting for Your CNC Laser Cutter: Cost vs. Value Considerations

When considering the purchase of a CNC laser cutter for metal in 2025, budgeting is a critical aspect that requires careful thought. The first step is to evaluate the cost of the machine itself, which can vary widely based on features, brand reputation, and capabilities. While it may be tempting to opt for the lowest-priced option, it’s essential to consider the long-term value the machine will provide. Investing in a reputable brand may come with a higher upfront cost, but it often leads to better reliability and lower maintenance expenses over time.

Beyond the initial purchase price, potential buyers should also take into account additional costs such as software, maintenance, and training. A CNC laser cutter that includes robust customer support and educational resources might incur a higher price but can significantly reduce operational frustrations in the long run. Therefore, understanding the total cost of ownership, which encompasses these factors, will help buyers make informed decisions that align with their budget, ensuring they find the perfect match for their cutting needs.

2025's Top 10 CNC Laser Cutters for Metal: Find Your Perfect Match!

| Model | Laser Power (W) | Max Cutting Thickness (mm) | Cutting Speed (m/min) | Price Range ($) |

|---|---|---|---|---|

| Model A | 1000 | 8 | 10 | 3000-5000 |

| Model B | 1500 | 10 | 12 | 5000-8000 |

| Model C | 2500 | 15 | 20 | 8000-12000 |

| Model D | 3000 | 20 | 25 | 12000-15000 |

| Model E | 4000 | 25 | 30 | 15000-20000 |

| Model F | 6000 | 30 | 35 | 20000-25000 |

| Model G | 8000 | 40 | 40 | 25000-30000 |

| Model H | 10000 | 50 | 45 | 30000-35000 |

| Model I | 12000 | 60 | 50 | 35000-40000 |

| Model J | 15000 | 70 | 60 | 40000-45000 |

Essential Tips for Maintaining Your CNC Laser Cutter for Longevity

Maintaining your CNC laser cutter is essential for ensuring its longevity and optimal performance. Regular maintenance not only prolongs the life of your equipment but also enhances its efficiency, reducing costs associated with repairs and downtime. One of the key tips for maintenance is to keep the lens and mirrors clean. Dust and debris can accumulate over time and significantly affect the cutting quality. Use a suitable lens cleaning solution and soft cloth to gently clean these components, and perform this task frequently.

Another important aspect is to regularly check and calibrate your machine. Ensuring that the laser is correctly aligned and the settings are appropriate for the material being cut can prevent unnecessary wear and tear. Additionally, pay attention to the cooling system as it helps prevent overheating during operation. Regularly inspect the coolant levels and replace the coolant as necessary to maintain effective cooling performance. These steps will help ensure that your CNC laser cutter operates efficiently for years to come.

Top 10 CNC Laser Cutters for Metal in 2025

This chart displays the cutting speed (in inches per minute) and the maximum thickness capacity (in inches) of the top 10 CNC laser cutters for metal in 2025. The data helps potential buyers to compare performance specifications before making a decision.

Innovative Technologies Shaping the Future of CNC Laser Cutting

The landscape of CNC laser cutting technology is rapidly evolving, driven by innovative advancements that are reshaping the industry. According to a recent report by MarketsandMarkets, the global CNC laser cutting machine market is projected to reach $8.89 billion by 2025, growing at a CAGR of 5.5%. This growth is largely fueled by the rising demand for precision-engineered components across various sectors, including automotive, aerospace, and manufacturing. As companies strive for efficiency and quality in their production processes, the integration of advanced technologies such as artificial intelligence and machine learning in CNC laser cutting systems is proving to be transformational.

Moreover, the introduction of fiber laser technology has marked a significant milestone in the field. Fiber lasers not only offer superior cutting speeds and enhanced material versatility compared to traditional CO2 lasers but also demonstrate remarkable efficiency in energy consumption. According to a report by Grand View Research, the fiber laser segment is anticipated to witness substantial growth, reaching over $5 billion by 2027. As businesses prioritize sustainability, these innovative technologies are paving the way for environmentally-friendly manufacturing practices, making CNC laser cutting an indispensable tool for modern production lines.

Related Posts

-

Unlocking the Future of Precision Manufacturing with CNC Machines and Industry 4.0 Insights

-

Mastering the Craft of Structural Steel Fabrication A Step by Step Tutorial

-

5 Best Tips for Maximizing Efficiency with CNC Fiber Laser Cutting Machines

-

7 Essential Benefits of Sheet Metal Laser Cutting for Modern Manufacturing

-

Unlocking the Secrets of Welding Tools: A Comprehensive Guide for Beginners

-

How to Utilize CNC Laser Cutting Technology for Maximizing Precision and Efficiency in Manufacturing

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms