What is Sheet Metal Laser Cutting and How Does It Work

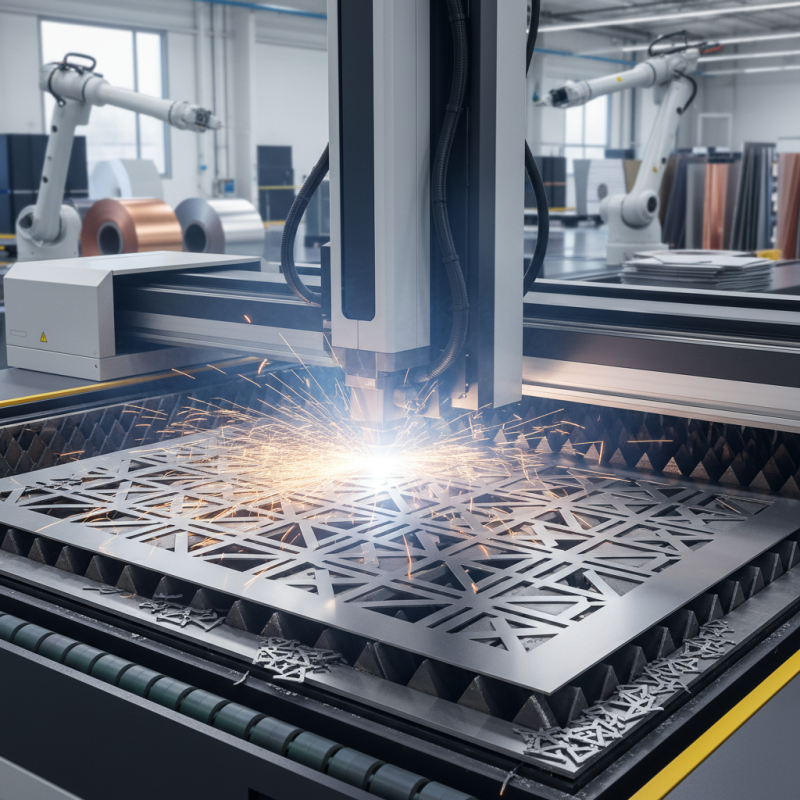

Sheet metal laser cutting has revolutionized the manufacturing industry by offering precision and efficiency in metal fabrication. This advanced technology utilizes focused laser beams to cut and engrave a wide variety of types of sheet metal, producing intricate designs with minimal material wastage. The process involves directing a high-powered laser onto the sheet metal surface, which melts, burns, or vaporizes the material, resulting in clean, accurate cuts.

One of the primary advantages of sheet metal laser cutting is its versatility. It can handle various materials, such as stainless steel, aluminum, and copper, making it an essential tool in diverse applications, from automotive to aerospace sectors. Moreover, this cutting method allows for rapid production speeds and can easily be integrated into automated systems, enhancing operational efficiency.

The effectiveness of sheet metal laser cutting lies not only in its speed and accuracy but also in its ability to create complex shapes that traditional cutting methods would struggle to achieve. As demand for customized components continues to grow, the importance of mastering this cutting-edge technology becomes increasingly significant for manufacturers striving to stay competitive in today’s fast-paced market.

Overview of Sheet Metal Laser Cutting Technology

Sheet metal laser cutting is a modern manufacturing process that utilizes focused laser beams to cut through various types of sheet metal with precision and efficiency. This technology has gained popularity due to its ability to produce intricate designs and complex shapes with minimal material waste. The process begins with the selection of suitable metal sheets, which are then loaded onto a cutting machine. The laser emits a concentrated beam of light that melts or vaporizes the metal along predetermined lines, creating clean and accurate cuts.

One of the key advantages of sheet metal laser cutting technology is its speed and versatility. It allows for high-speed cutting, enabling manufacturers to meet tight production deadlines without compromising on quality. Additionally, the technology can be adapted to work with different materials, including steel, aluminum, and copper, making it a preferred choice for various industries. The automated nature of laser cutting systems also reduces the need for manual labor, lowering production costs and enhancing overall efficiency. As manufacturers increasingly adopt this technology, its role in shaping the future of metal fabrication continues to grow.

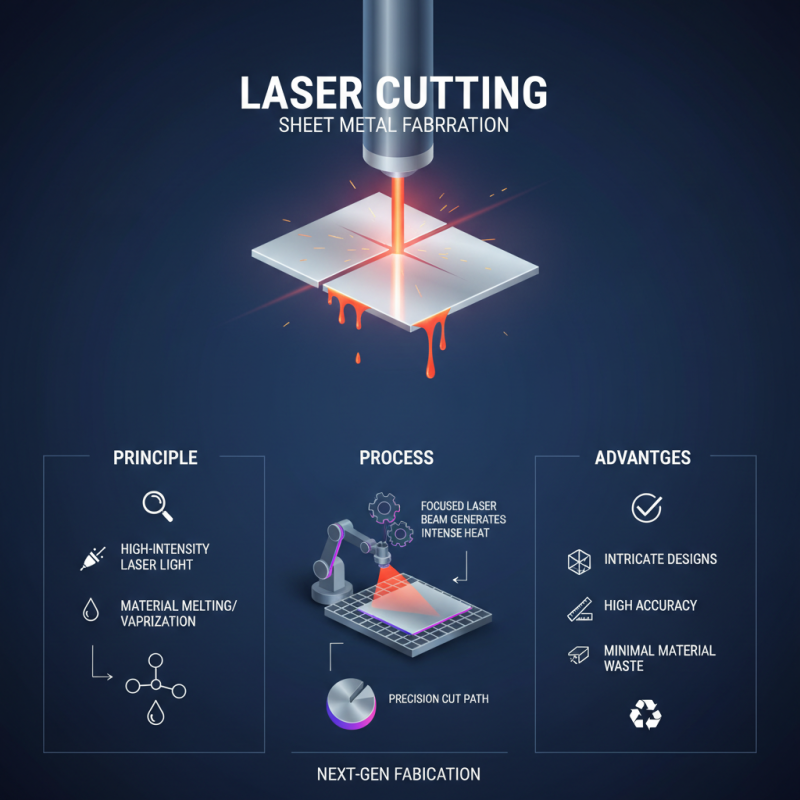

Principles of Laser Cutting in Sheet Metal Fabrication

Laser cutting is a sophisticated method employed in sheet metal fabrication that exploits the focused energy of a laser beam to precisely cut through metal sheets. The fundamental principle behind this technique lies in the interaction of high-intensity laser light with the material. When the laser beam is directed onto the surface of the sheet metal, it generates intense heat, melting or vaporizing the material in its path. This allows for intricate designs and shapes to be achieved with high accuracy and minimal material waste.

The process typically involves a few essential components, including a laser source, a cutting head, and a motion control system. The laser source produces the beam, which is then directed through lenses and mirrors to focus the light onto the sheet metal. The cutting head moves swiftly across the metal's surface, guided by computer numerical control (CNC) systems, ensuring that the laser cuts along the predetermined pattern. The efficiency and precision of laser cutting contribute to its growing popularity in various industries, enabling manufacturers to create complex geometries and achieve tight tolerances that are often difficult to accomplish with traditional cutting methods.

Types of Lasers Used in Metal Cutting Processes

When it comes to sheet metal laser cutting, one of the most critical aspects is the type of laser technology employed in the process. The most commonly used laser types include CO2 lasers, fiber lasers, and Nd:YAG lasers. CO2 lasers, known for their efficiency and high power output, are often used for cutting thicker materials. They operate by emitting a beam of light in the 10.6 micron wavelength range, which is highly absorbed by metals, making them ideal for various metal cutting applications.

Fiber lasers, on the other hand, utilize a different mechanism; they rely on a solid-state medium and a wavelength of approximately 1.06 microns. This results in a much higher beam quality and efficiency, particularly beneficial for cutting thin metals and highly reflective materials like aluminum and copper. The compact design and lower maintenance costs associated with fiber lasers have made them increasingly popular in various manufacturing sectors. Nd:YAG lasers, which use neodymium doped yttrium aluminum garnet, provide versatility in applications, including cutting and engraving, though they are more commonly used in precision tasks due to their focused beam capabilities. Each type of laser offers unique advantages, allowing manufacturers to select the most suitable technology based on their specific needs and material requirements.

Types of Lasers Used in Metal Cutting Processes

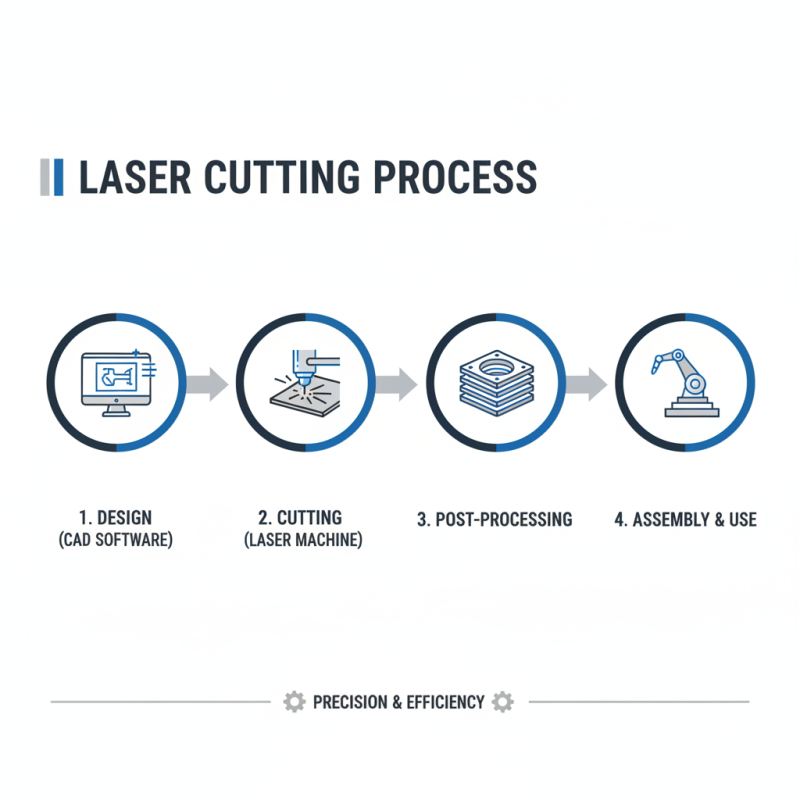

Step-by-Step Process of Laser Cutting Sheet Metal

Laser cutting sheet metal is a highly precise industrial process that involves several well-defined steps. The first step begins with design, where a digital blueprint of the desired component is created using CAD (Computer-Aided Design) software. This design is critical as it dictates the dimensions, shapes, and specifications that the laser cutting machine will follow.

Once the design is prepared, the next phase involves setting up the laser cutting machine. This includes loading the sheet metal onto the cutting bed and adjusting the machine settings according to the material thickness and type. The laser cutter is then calibrated to ensure that the focus and cutting speed are optimized for clean edges and minimal waste. After these preparations, the machine is ready to begin the cutting process, where a high-powered laser beam is directed onto the sheet metal, melting or vaporizing the material to create the desired shapes.

Finally, post-processing is conducted, which may involve removing the cut pieces, cleaning any residual debris, and performing quality checks to ensure that the final products meet the required standards. This step is crucial for maintaining accuracy and ensuring that the components are ready for assembly or further manufacturing processes.

Applications and Benefits of Laser Cut Sheet Metal Techniques

Laser cutting has revolutionized the sheet metal industry by enabling precision fabrication that meets the stringent requirements of various applications. One of the primary advantages of laser-cut sheet metal is its ability to produce intricate designs and complex geometries with minimal material waste. This is particularly beneficial in industries such as automotive, aerospace, and construction, where tight tolerances and efficiency are vital. The technology is also increasingly used in art and design projects due to its capability to create detailed patterns that traditional methods might struggle to replicate.

In addition to precision, laser cutting offers flexibility in handling different types of materials, including steel, aluminum, and copper. This versatility allows manufacturers to adapt quickly to changing market demands, producing both large batches and custom pieces without the need for extensive retooling. Furthermore, the process itself is relatively fast, improving turnaround times while maintaining high-quality standards.

Tips for achieving optimal results in laser cutting include ensuring proper material thickness and consistency, maintaining the cutting equipment to prevent malfunctions, and selecting the right parameters based on the material type. Regularly reviewing and updating techniques can also help in capitalizing on new advancements in laser technology, ultimately enhancing production efficiency and product quality.

What is Sheet Metal Laser Cutting and How Does It Work - Applications and Benefits of Laser Cut Sheet Metal Techniques

| Application | Material Type | Thickness Range (mm) | Benefits |

|---|---|---|---|

| Automotive Parts | Stainless Steel | 0.5 - 5 | High precision, reduced waste |

| Aerospace Components | Aluminum | 0.5 - 6 | Lightweight, complex shapes |

| Construction Fabrication | Mild Steel | 1 - 20 | Durability, quick production |

| Electronics Enclosures | Copper | 0.5 - 3 | Excellent conductivity, precise cuts |

| Furniture Design | Acrylic | 2 - 10 | Aesthetic appeal, intricate designs |

Related Posts

-

10 Best Sheet Metal Prototyping Tips for 2023 to Boost Your Production Efficiency

-

How to Maximize Efficiency with CNC Laser Cutting in Your Manufacturing Process

-

Innovative Techniques in Sheet Metal Manufacturing You Might Not Know

-

7 Essential Benefits of Sheet Metal Laser Cutting for Modern Manufacturing

-

Exploring Alternatives to CNC Laser Cutting Machines for Precision Manufacturing

-

How to Utilize CNC Laser Cutting Technology for Maximizing Precision and Efficiency in Manufacturing

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms