10 Best Steel Laser Cutting Machines for Precision and Efficiency

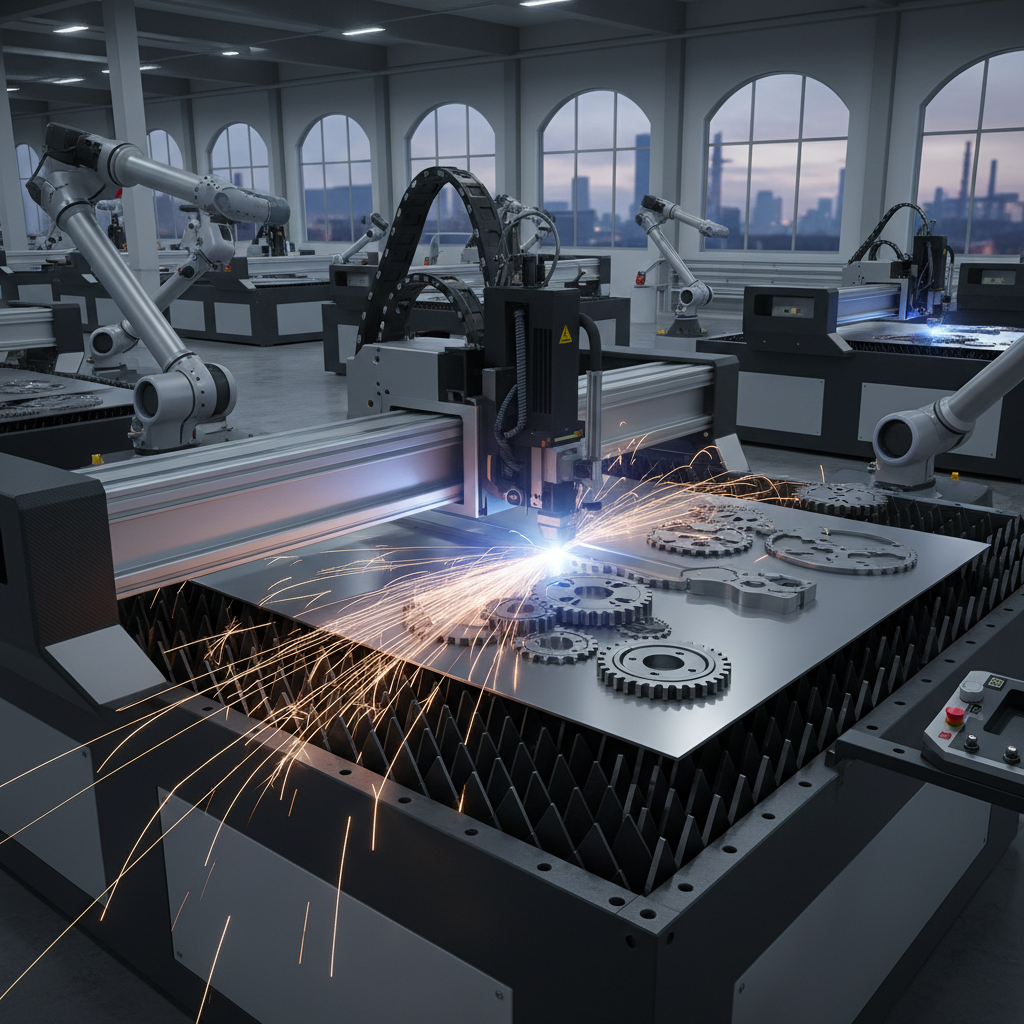

In the modern manufacturing landscape, precision and efficiency are paramount, especially when it comes to metal processing. Steel laser cutting machines have emerged as vital tools that empower industries to achieve remarkable accuracy in their cutting operations. As John Smith, a renowned expert in laser technology, aptly states, "The evolution of steel laser cutting machines has not only enhanced production capabilities but also redefined the standards of quality in metal fabrication." This evolution is a response to the growing demand for high-quality steel parts in various sectors, including automotive, aerospace, and construction.

With advancements in laser technology, the latest steel laser cutting machines offer unparalleled precision and speed, making them a preferred choice for manufacturers worldwide. The integration of cutting-edge features, such as automated settings and real-time monitoring, ensures that operators can achieve optimal results with minimal waste. As we explore the ten best steel laser cutting machines available today, we will examine how these innovations are setting new benchmarks for efficiency and performance, enabling businesses to stay competitive in an ever-evolving industry landscape.

Top Features to Look for in Steel Laser Cutting Machines

When selecting a steel laser cutting machine, several key features should be prioritized to enhance precision and efficiency. Firstly, the laser type is crucial; CO2 and fiber lasers are the most common, with fiber lasers generally offering better efficiency for cutting thick metals. The power output of the machine significantly impacts cutting speed and material thickness capabilities, making it essential to choose a model that aligns with your specific requirements.

Another important factor is the machine's cutting table size, which determines the maximum sheet size that can be processed. A larger table allows for greater flexibility in cutting bigger pieces or multiple smaller items in a single run. Additionally, consider the machine’s software compatibility and user interface; intuitive software can streamline operations, improve workflow, and reduce setup times. Furthermore, an integrated cooling system is vital for maintaining optimal performance during extended cutting sessions, ensuring that both the machine and materials remain at a stable temperature for consistent results.

How to Choose the Right Laser Cutting Machine for Your Needs

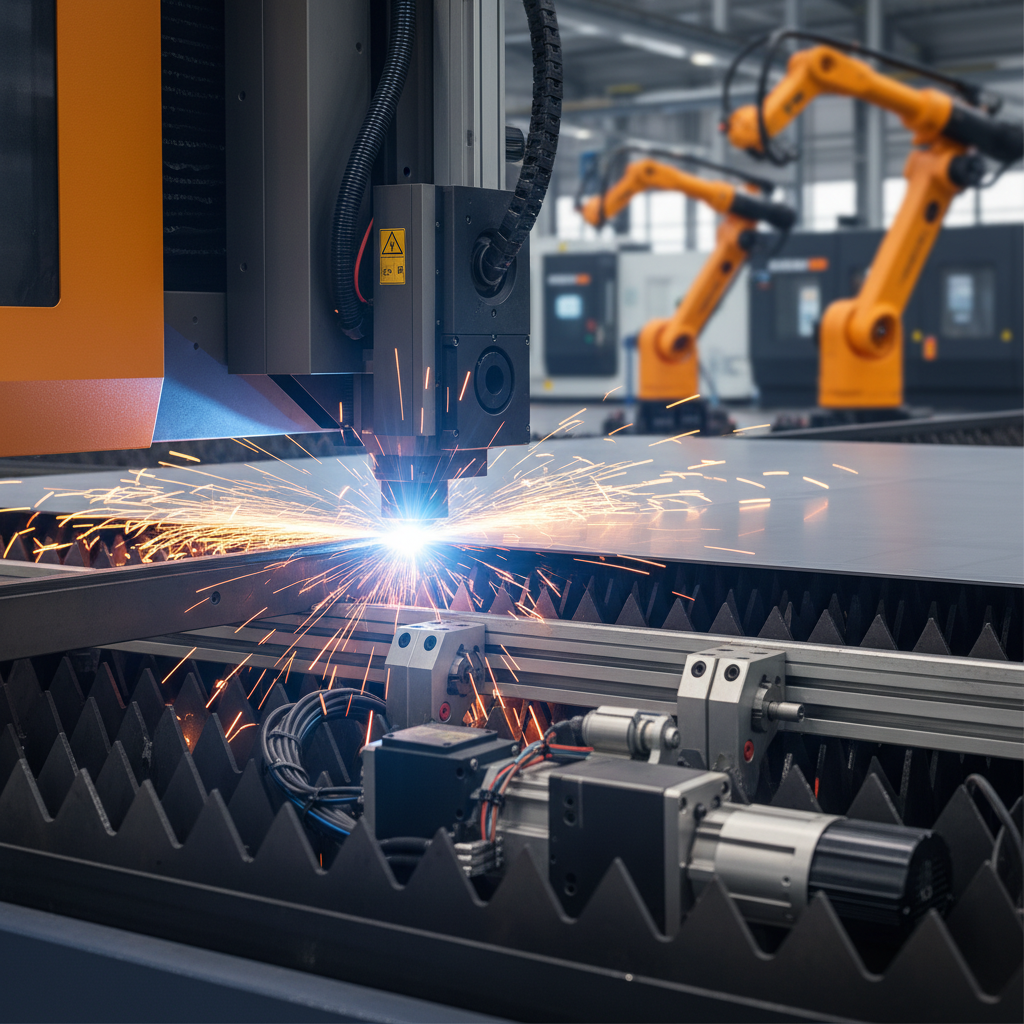

When selecting a laser cutting machine for steel, it’s essential to consider several factors that will optimize precision and efficiency for your specific needs. According to a report by MarketsandMarkets, the global laser cutting machine market is projected to reach $6.75 billion by 2025, indicating significant advancements in technology and applications. Look for machines with appropriate wattage; higher wattage typically allows for cutting thicker materials faster and with cleaner edges.

Tips: Assess your production volume and typical steel thickness to determine the correct wattage. For instance, machines with power ranging from 1,000W to 2,000W are often ideal for thin sheets, while those with 3,000W or higher suit thicker materials.

Moreover, software compatibility is crucial. Many modern laser cutting machines come with advanced software that enhances design capabilities. According to industry insights, integrating automation can increase efficiency by up to 30%. Always ensure that the machine offers compatible software that fits into your existing workflow.

Tips: Research the integration options and software features of potential machines to streamline your production process. Also, consider the availability of technical support and spare parts, as these factors can significantly affect maintenance and operational downtime.

Comparison of Laser Cutting Machines Based on Power and Cutting Speed

Comparative Analysis of the Leading Steel Laser Cutting Brands

When considering the best steel laser cutting machines, a comparative analysis of leading brands reveals significant variations in precision and efficiency. The market offers a diverse range of machines tailored to different industrial needs, making it crucial for businesses to evaluate their specific requirements before making a choice. Advanced features such as software compatibility, cutting speed, and material thickness capabilities come into play. Manufacturers are continuously innovating to include more efficient cutting technologies that directly impact production rates.

Tips: When selecting a steel laser cutting machine, prioritize models that provide real-time monitoring capabilities. This feature allows for immediate adjustments during the cutting process, enhancing overall precision and quality. Additionally, assess the machine's ease of maintenance, as a user-friendly design can reduce downtime and maintenance costs.

Another aspect to consider is the support and training provided by the manufacturer. Comprehensive training programs can significantly improve your team’s operational skills, leading to better utilization of the machine’s capabilities and improved efficiency. Always review post-purchase support options to ensure your investment remains protected and your staff is well-equipped to leverage the technology effectively.

Maintenance Tips for Keeping Your Laser Cutting Machine in Top Shape

Maintaining laser cutting machines is vital for ensuring precision and efficiency in steel fabrication. According to a report by the International Laser Manufacturing Association, regular maintenance can increase the lifespan of laser cutting machines by up to 30%. This is crucial for industries where uptime is directly linked to productivity and profitability. Key maintenance tips include regularly checking and cleaning the optics to prevent debris buildup, which can impair beam quality and result in uneven cuts. Additionally, keeping the machine properly lubricated reduces friction and wear on moving parts, further enhancing performance.

Another essential aspect of maintenance is software updates. The technology behind laser cutting is rapidly evolving, and staying current with the latest software can improve operational efficiency. According to a study by the Machine Tool Technology Association, implementing modern software solutions can lead to a reduction in material waste by as much as 15%. Operators should also perform routine inspections of the cooling system, as maintaining optimal temperature is critical for preventing overheating and damage to the laser source. By adhering to these maintenance practices, manufacturers can ensure their laser cutting machines deliver reliable performance and maintain high-quality output.

10 Best Steel Laser Cutting Machines for Precision and Efficiency

| Model | Cutting Power (W) | Max Cutting Thickness (mm) | Speed (m/min) | Efficiency Rating |

|---|---|---|---|---|

| Model A | 1500 | 20 | 15 | High |

| Model B | 2000 | 25 | 18 | Very High |

| Model C | 2500 | 30 | 20 | Moderate |

| Model D | 3000 | 35 | 22 | High |

| Model E | 3500 | 40 | 25 | Very High |

Maintenance Tips for Keeping Your Laser Cutting Machine in Top Shape

| Tip | Frequency | Details |

|---|---|---|

| Check Lens and Mirrors | Weekly | Clean and inspect for residue or damage. |

| Coolant Levels | Monthly | Ensure proper levels of coolant to avoid overheating. |

| Lubricate Moving Parts | Monthly | Apply lubricant to reduce friction and wear. |

| Software Updates | Quarterly | Check for and install any available software updates. |

| Routine Inspections | Annually | Professional evaluation of machine performance. |

Cost Considerations: Budgeting for Your Steel Laser Cutting Equipment

When investing in steel laser cutting machines, cost considerations are paramount for businesses aiming for precision and efficiency without breaking the bank. According to a report by MarketsandMarkets, the global laser cutting machine market was valued at approximately $3.4 billion in 2020 and is projected to reach $6.6 billion by 2026, growing at a compound annual growth rate (CAGR) of 11.4%. This significant market growth highlights the increasing demand for laser cutting technologies, particularly in sectors like automotive, aerospace, and metal fabrication.

Budgeting for steel laser cutting equipment involves not just the initial purchase price but also operational costs, maintenance, and potential downtime. A study by ResearchAndMarkets indicated that operational costs can account for nearly 30% of total expenses associated with laser cutting equipment. Therefore, businesses must accurately project total cost of ownership (TCO) when evaluating machine options. It's essential to consider high-quality machines that offer improved energy efficiency and speed, which can lead to substantial savings over time. By carefully evaluating these financial factors, companies can ensure they select the best equipment to enhance their production capabilities and maintain competitiveness in the market.

Related Posts

-

How to Maximize Efficiency with CNC Laser Cutting in Your Manufacturing Process

-

7 Essential Benefits of Sheet Metal Laser Cutting for Modern Manufacturing

-

7 Best Laser Machine Innovations to Transform Your Manufacturing Process

-

Unlocking the Secrets of Welding Tools: A Comprehensive Guide for Beginners

-

10 Best Sheet Metal Prototyping Tips for 2023 to Boost Your Production Efficiency

-

Mastering the Craft of Structural Steel Fabrication A Step by Step Tutorial

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms