What is Sheet Metal Prototyping Understanding Its Benefits and Industry Impact

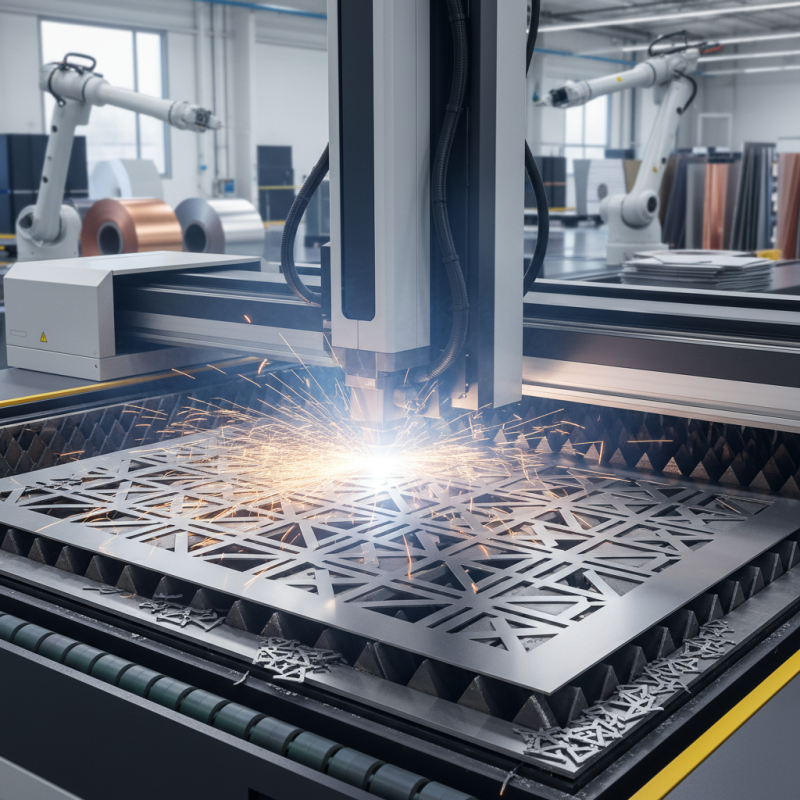

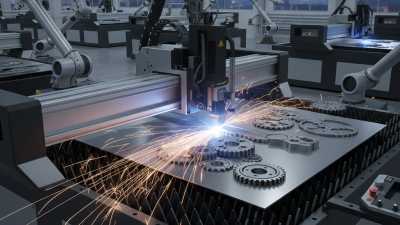

Sheet metal prototyping is a critical process in the manufacturing industry, characterized by its ability to create precise and durable components efficiently. As we move towards more advanced manufacturing technologies, understanding the benefits and implications of sheet metal prototyping becomes increasingly important. Expert in the field, Dr. Amanda Lee, emphasizes, "The ability to prototype with sheet metal not only accelerates product development but also significantly reduces costs while maintaining high quality." This shift towards more streamlined processes is transforming how industries approach product design and production.

In an era of rapid innovation, sheet metal prototyping plays a pivotal role in various sectors, including aerospace, automotive, and electronics. The advantages of this method are manifold: it allows for quick iterations of design, enhances collaboration between design and production teams, and ultimately leads to better end products. As companies strive for competitive advantages, the integration of efficient prototyping techniques will be essential in meeting consumer demands and staying ahead in the market.

As we explore the trends and impacts of sheet metal prototyping leading up to 2025, it is crucial to evaluate how these practices are shaping industries. The evolution of materials, technology, and methodologies will influence not only cost efficiency but also the sustainability of manufacturing practices in the future. Understanding these dynamics will be key to navigating the challenges and opportunities present in the ever-evolving landscape of manufacturing.

Read more »

By:James - December 6, 2025

By:James - December 6, 2025

By:Sophia - December 1, 2025

By:Sophia - December 1, 2025

By:James - November 27, 2025

By:James - November 27, 2025

By:Clara - November 22, 2025

By:Clara - November 22, 2025

By:Clara - November 19, 2025

By:Clara - November 19, 2025

By:James - November 12, 2025

By:James - November 12, 2025

By:Sophia - November 7, 2025

By:Sophia - November 7, 2025

By:Clara - November 4, 2025

By:Clara - November 4, 2025

By:Clara - October 26, 2025

By:Clara - October 26, 2025

By:Clara - October 21, 2025

By:Clara - October 21, 2025

By:Clara - October 17, 2025

By:Clara - October 17, 2025

By:Sophia - October 12, 2025

By:Sophia - October 12, 2025

By:James - October 8, 2025

By:James - October 8, 2025

By:Clara - October 4, 2025

By:Clara - October 4, 2025

By:James - September 29, 2025

By:James - September 29, 2025